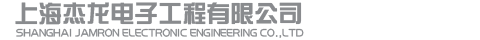

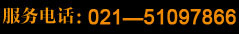

MANIX+AF-2500全自动芯片成型系统JR

AF-2500 ADJUSTABLE SMT LEAD FORM SYSTEM

自动SMT芯片切脚/成型系统

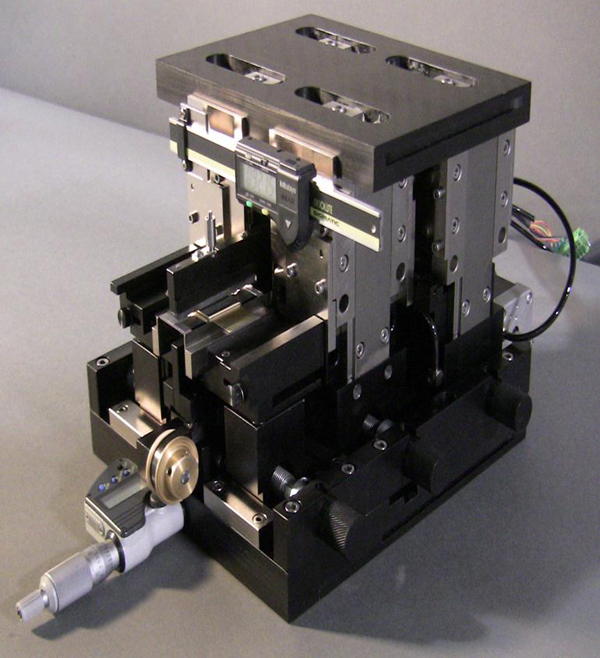

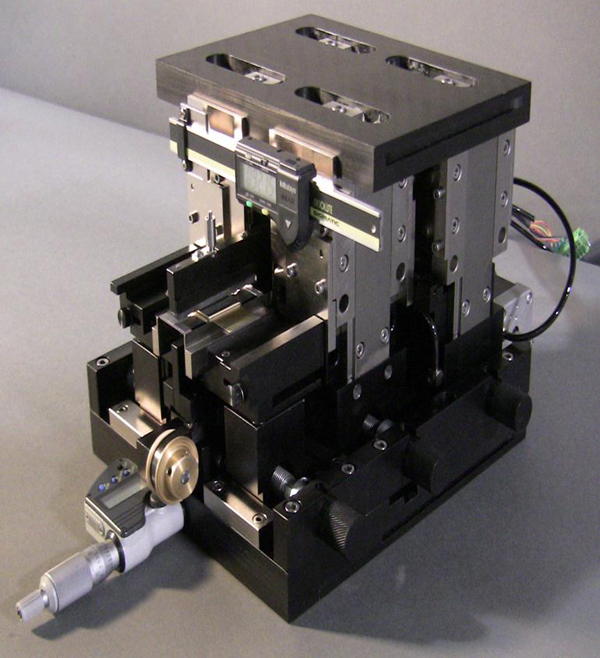

The Manix AF-2500 is the industry’s first automatic flat pack trim and form system. The system is capable of cutting and forming two opposing sides of a component simultaneously to a SMT or reflow form.

AF-2500成型系统为国际上首台自动SMT芯片切角成形系统,系统配置双边双工位成型切脚/成型模具,自动完成芯片引脚成型和切脚步骤。

The system is fully adjustable for overall cut length, stand-off height, footpad, component lead thickness, bend radii, component body size, and body to first bend.

系统多项成型参数可调,包括总切割长度、站高、焊接面长度、引脚厚度、成型半径、本体尺寸、肩宽等参数可调。

PLC Controller includes operational software and a component library which can store all pertinent component information including micrometer settings, and whether the part is two or four sided.

PLC控制器包括操作软件和元器件库,包括成型参数、器件类型等。

Forming and cutting die includes a motorized transport system which eliminates operator handling.

成型模具和切割模具,包括器件自动传输,避免人工操作。

Centering station can accurately center all two and four sided flat pack components, including bottom and top lead attachment components.

器件中心定位装置可以精确定位双边和四边引脚的器件,包括顶部引脚和底部引脚器件。

Safety interlocks prevent operator error.

安全互锁装置。

Component handling is at a minimum. The component is transported through the various stages automatically. A pick device gently transports the component to the form tooling and then to the cut tooling.

快速放置器件到上料工位,器件可在上料工位、成型工位、切脚工位自动传输。

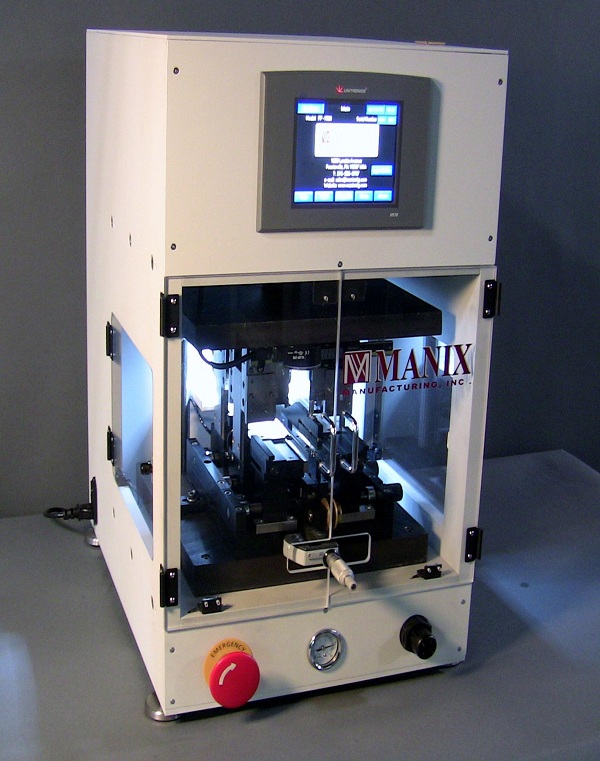

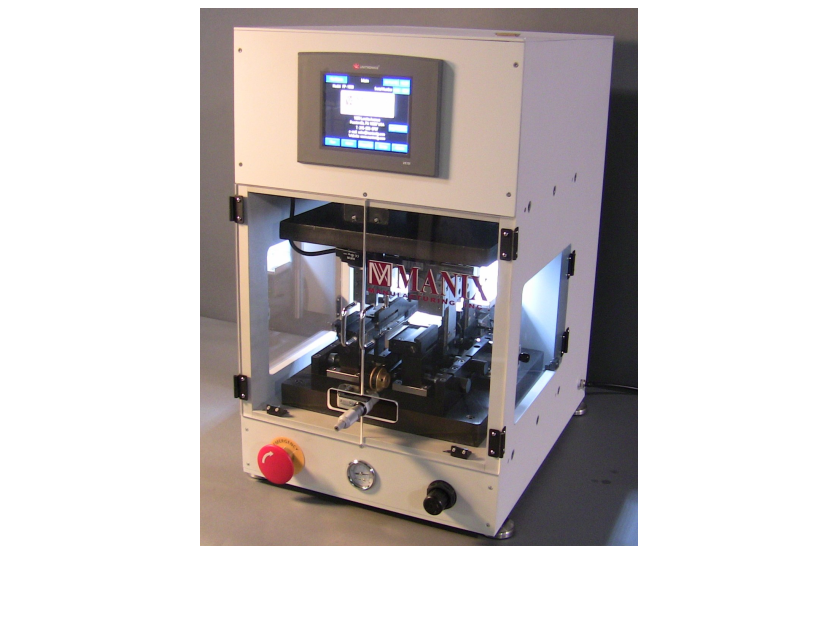

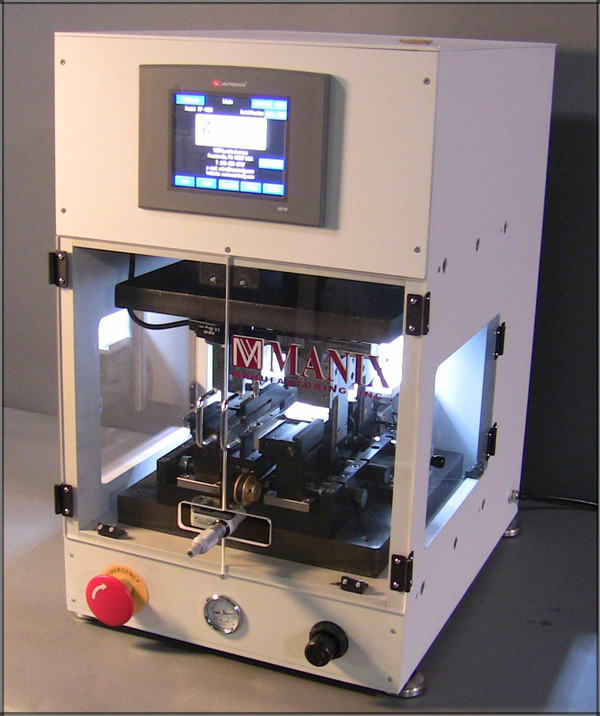

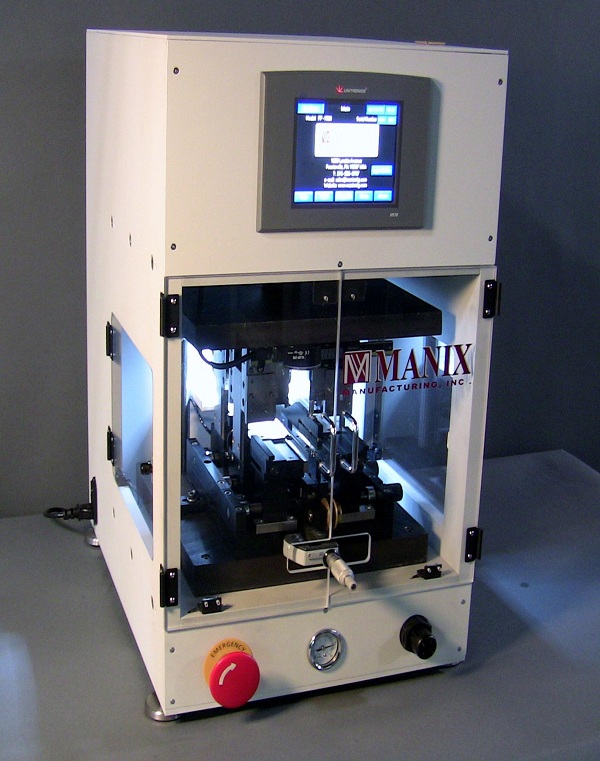

The AF-2500 includes a PLC controller with operation software, a rugged pneumatic press, a motorized transport mechanism, a fully adjustable forming and cutting die, and a centering device that quickly aligns FP components whether top or bottom brazed, and or standard side lead exit. Adjustment software and a component library ease system set-up. Doors with interlocks, LED lighting and AIRCLEAN cut lead removal are standard.

系统包括PLC控制器及控制软件,坚固稳定的气压装置、电机驱动传输装置、可调式切割成型模具、器件中心定位装置、元器件成型参数数据库、安全门互锁保护、LED照明、压缩空气清洁装置等。

AF-2500 FEATURES AND BENEFITS

☆SYSTEM CONTROLS 系统控制

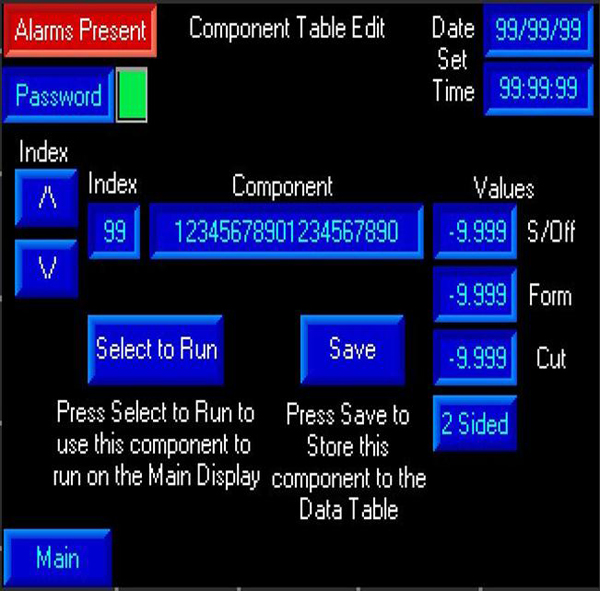

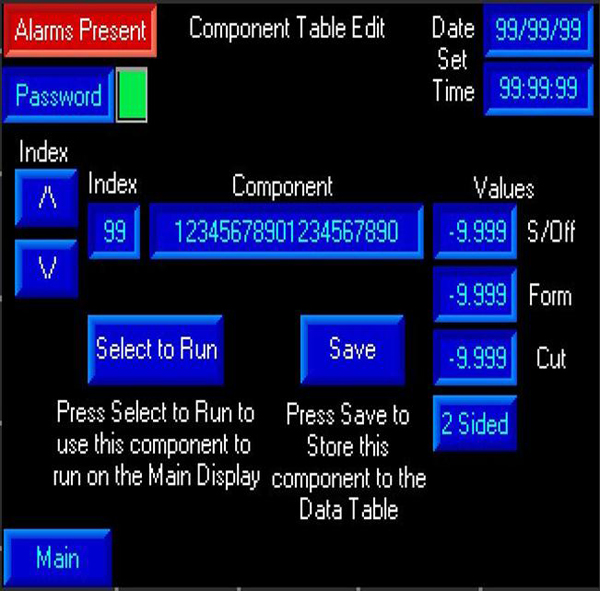

The software and PLC controller are easy to use. A menu-driven controller assures mistake-free operation. A component editor screen retains all of the pertinent information for each component; it can be recalled at a touch of a screen button. Micrometer settings, component name, and whether or not the component is two or four sided is some of the stored information. Maintenance levels and component editor are password protected. A setup level instructs the operator on set-up. Alarm menus notify if an alarm is present, if present the system will not operate.

PLC控制器操作简便,菜单式操作,避免操作失误。器件编辑屏幕显示所有器件成型参数信息,包括千分尺设置、双边/四边类型、具有编辑和系统维护密码保护、故障报警提示等功能。

☆ADJUSTABLE DIE 可调模具

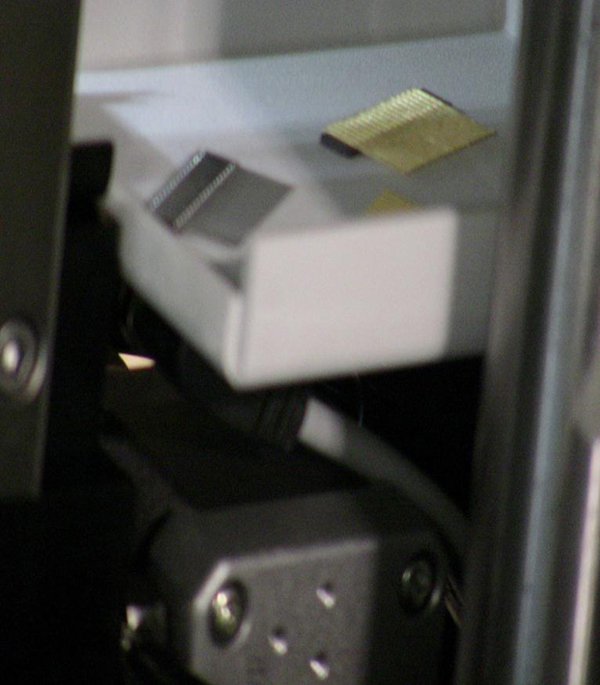

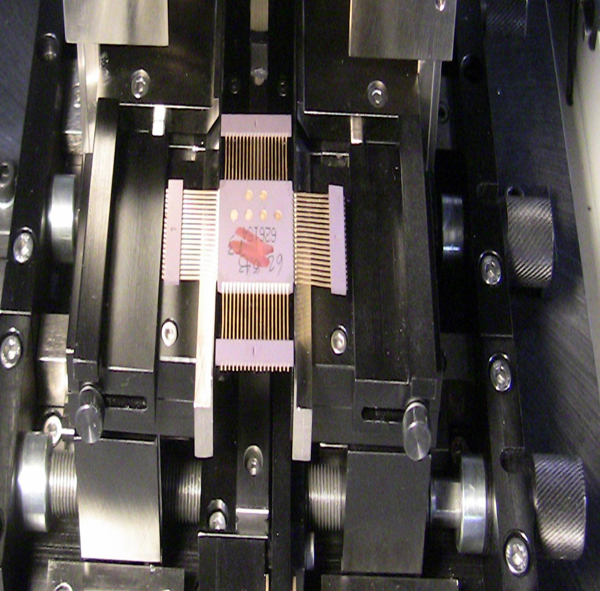

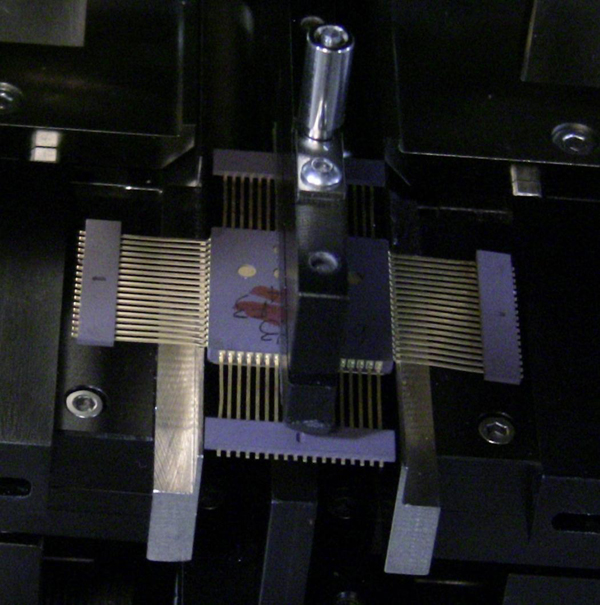

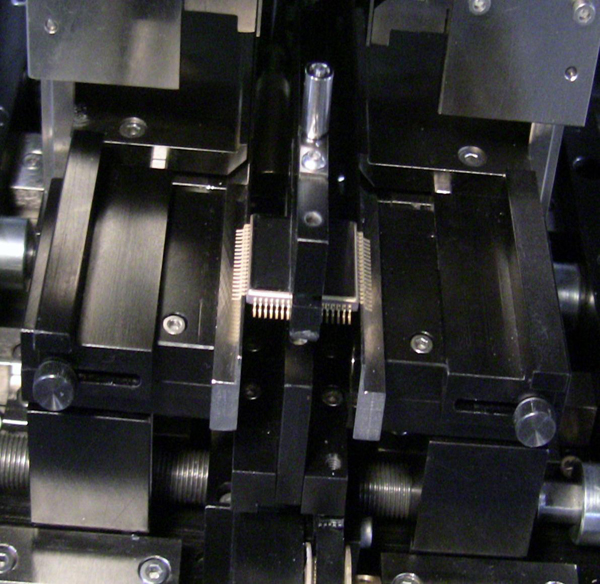

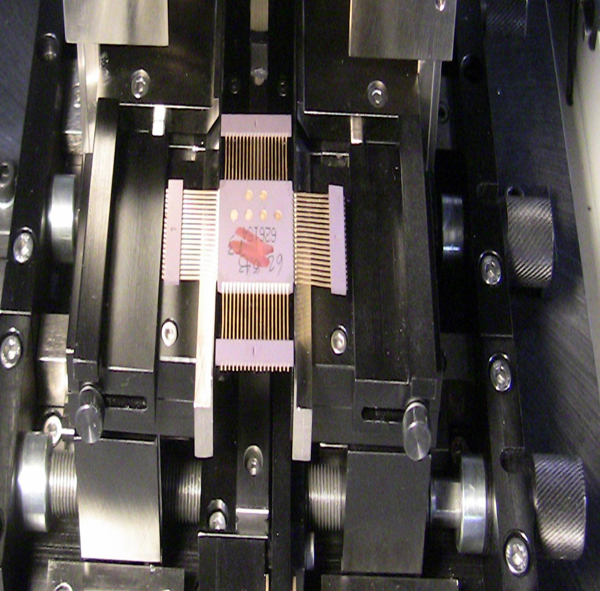

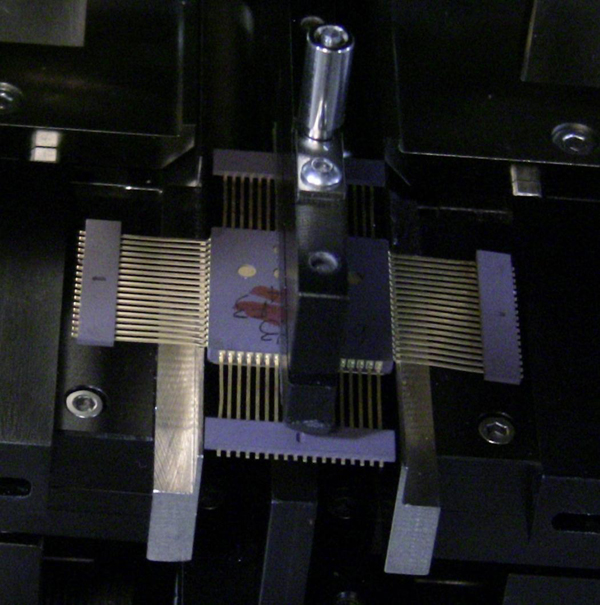

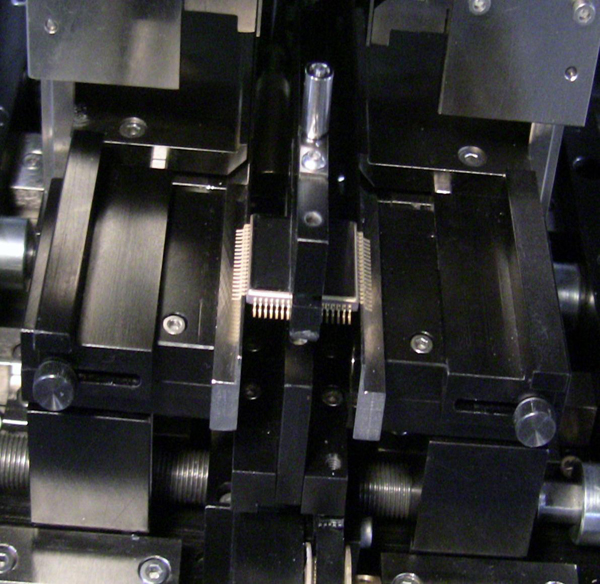

The AF-2500 forming and cutting die is fully adjustable for component body size, footpad length, stand-off height, lead thickness, bend radii, and body to first bend distance. The three stage die forms and cuts two sides of a component simultaneously. The first stage centers the component, ensuring equal forming and cutting. The second forms the component to a reflow or SMT form, while retaining the tie bar. The last stage cuts the component to the proper footpad length. A transport system includes a cushioned pickup head and a motorized conveyor. Optional quick change inserts are available for varying lead thicknesses and inside bend radii. Two lead screw thumbscrews adjust all other dimensions.

AF-2500双边可调模具,可根据器件类型及成型工艺要求调节各项参数,包括总切割长度、站高、焊接面长度、引脚厚度、成型半径、本体尺寸、肩宽等参数。三工位模具可同时成型和切割器件双边的引脚,第一工位用于器件中心定位,第二工位用于SMT成型,第三工位切割引脚到所需的焊接面长度。内置传输系统,包括缓冲式器件拾取装置和电机驱动传动轨道,快速更换的成型模块(选件),用于不同的引脚厚度和成型半径。两个丝杆调节旋纽可调整其它各项成型参数。

☆AIRCLEAN, LIGHTING AND MORE 清洁照明

Troublesome offcut leads and cut tie bars can be difficult to remove. The AF-2500 includes AIRCLEAN, a mechanism which directs air at the cut leads and blows them into a waste collection bin. The AIRCLEAN activates for a few seconds after the cutting stage.

Two LED lights which can be turned off and on illuminate the entire work area, making viewing easy.

Interlock switches prevent machine operation if either the side viewing windows or the two front doors are open. The PLC prompts the operator of an alarm condition. Simply close the doors and operation can continue.

系统包括压缩空气清洁装置,引导压缩空气将切下的引脚吹到废料收集盒内,清洁装置可在切割引脚后自动启动数秒钟清洁模具。

内置两个LED照明灯,方便操作观察。

前门和侧板安全互锁装置确保操作安全,PLC安全状态报警提示。

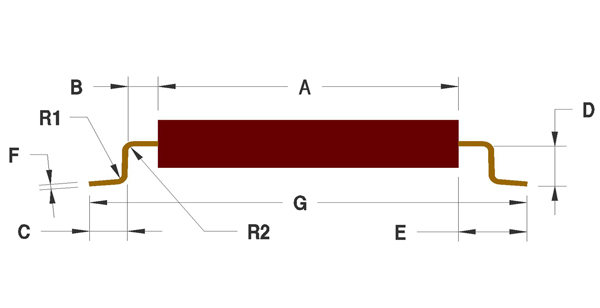

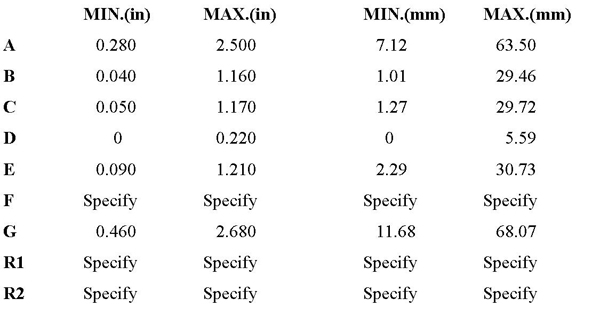

AF-2500 CUTTING AND FORMING SPECIFICATIONS

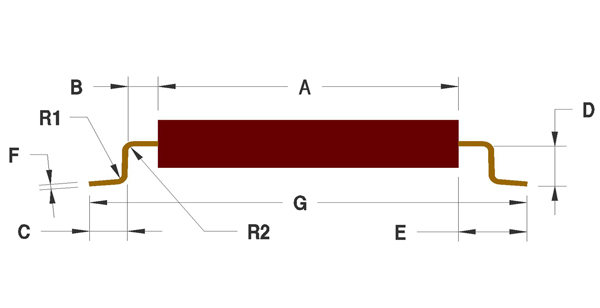

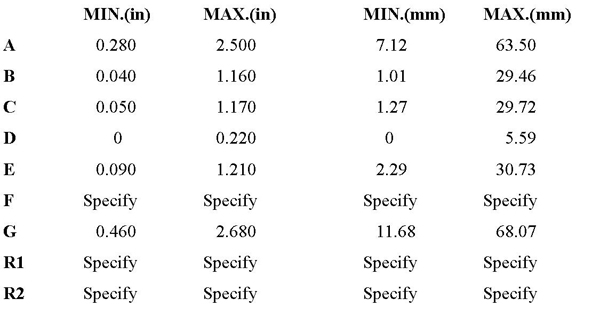

Please Note: Dimensions F and R1/R2 are tooling dependent. Quick change inserts are fabricated to your exacting dimensions. Specifications are dependent on each other. Larger B dimension will reduce maximum C dimension and the opposite is true. If A is a maximum, B and C are at minimums.

F和R1/R2尺寸与可更换式模块有关,加大B的尺寸将对应减小C的尺寸,如果器件本体尺寸A达到最大,对应B和C将会接近最小尺寸。

AF-2500 SEQUENCE OF OPERATION

Access the COMPONENT TABLE EDIT screen and either choose an existing component stored in the library or create a new one from scratch. Once chosen, depress SELECT TO RUN.

根据器件参数编辑屏幕和内存的器件目录,选择一种器件即可开始运行成型程序。

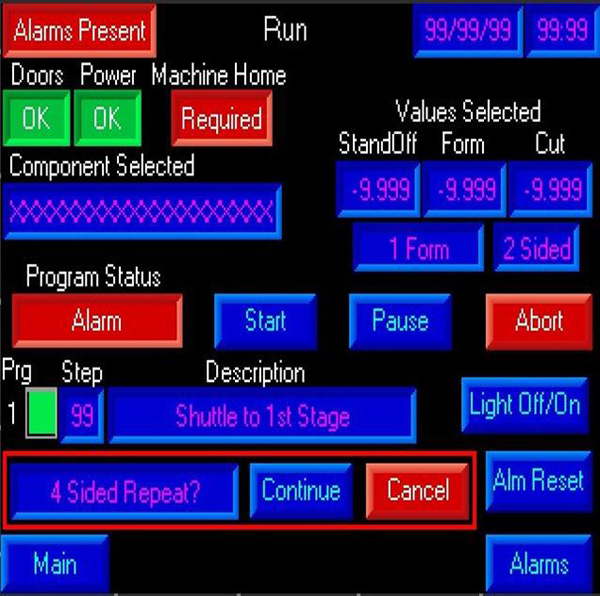

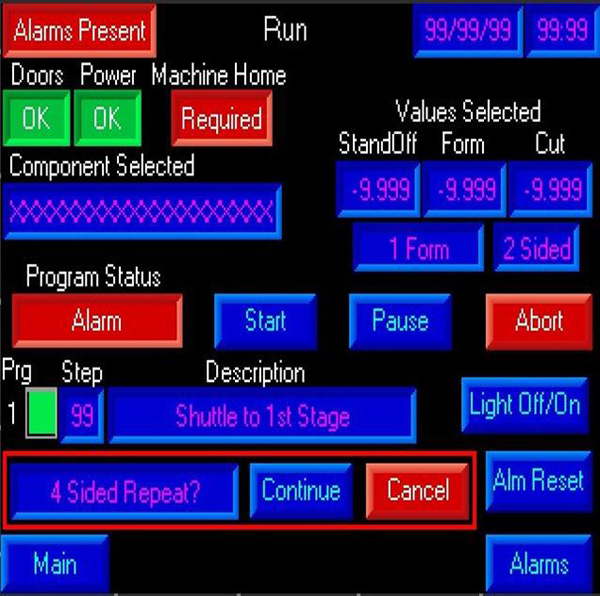

From the RUN screen, transfer the micrometer settings from the VALUES SELECTED and set the micrometers to those settings. Before depressing the START button, load the component onto the adjustable centering station ,Rotate the knurled knob until the centering anvils just touch the component body. If the component is a bottom lead attached component, use the adjustable lead tip centering station. Once centered, the system is ready to run.

根据运行屏幕中的设置参数,调节千分尺设置,将器件放置到中心定位装置上,调节中心定位旋钮至到夹具正好接触器件本体,启动START按钮。如果引脚从器件底部引出,可采用引脚中心定位装置。

AF-2500 SEQUENCE OF OPERATION

Once the component is centered, close the safety doors and simply depress the RUN button. The system will actuate automatically. The pick-up head will move forward and gently lift the component off of the centering station and transport the component to the forming stage. Once delivered to the forming stage, the cylinder will lower and form the component to a reflow configuration, retaining the tie bar, ensuring no lead deformation during transport. After forming, the component moves to the cut stage. The cylinder then lowers and cuts the leads to the correct dimension specified.

放置器件关闭安全门后启动成型程序,系统将自动运行,器件拾取头自动将器件放置到成型工位进行成型,完成后再自动移到切脚工位进行自动切割。

After cutting, the cut tooling will remain closed, encapsulating the component leads, while the AIRCLEAN system activates, depositing off cuts or tie bars into a collection bin, ensuring clean operation each and every time. Once completed, the component is transported back to the centering station. The operator will either remove and replace for a new component to be formed and cut, or rotate 90 degrees to form and cut the adjacent side og leads if it is a four sided component. The PLC screen will prompt the operator to replace or rotate the component. Simply depress the START button and the cycle will repeat.

每次完成切割后,系统启动气压清洁程序,将切下的引脚、碎屑清理到收集盒内,再将器件送回到中心定位装置上,PLC提示操作者将器件旋转90°后成型另外两边引脚,或重新放置新的器件进行成型。

LOCATION OF MAJOR COMPONENTS

结构布局:

PNEUMATIC PRESS

PLC CONTROLLER

AF-2500 CUTTING/FORMING DIE

LED LIGHTING

SAFETY DOORS W/INTERLOCKS

EMERGENCY STOP, AIR GUAGE, AND REGULATOR

Specifications 技术参数:

Dimensions: 19.5”W X 20.5D X 25.5H 495mm X 521mm X648mm

Weight: 250 lbs./114 kgs.

Air: 80 psi dry air required.

Connection: 1/4” or 6mm Tube

Electrical: 220 VAC single phase Switching power supply.

AF-2500 ACCESSORIES 辅助工具:

FP-TBC Tie Bar Corner Removal Tool

引线框边角切割装置

Quickly remove the ceramic corners of Tie Bars on flat pack components. Simply place the component into the tool and lower the handle. Tie bar corners will snap off, leaving the tie bars connected to the leads, ready now for the AF-2500 cutting and forming system.

快速安全切割陶瓷引脚边框的四角,只需将器件放入定位夹持装置,按压切割手柄,即可将陶瓷引脚安全折断去除,避免引脚变型损坏。

M891 Component Measuring Tool

器件站高测试装置

Lead to body exit can vary, making standoff height setting troublesome. The M891 quickly measure this dimension, ensuring accurate standoff during forming.

快速准确测量器件成型后焊接面到器件底部之间的站高,满足PCB板实际工艺要求。